Quality Management Policy

Quality at CASCO Valve is not just only controlled but it is 100% assured. CASCO maintain strictly quality standards that confirm to international quality Standard. Strictly Inspection and Testing is being maintained at all stage of inputs raw material, Machining and different assembly levels and manufacturing procedure to assure trouble free performance of the product year after year. Continual improvement is a part of our business Policy. CASCO provide best engineering solution for the customer's requirement

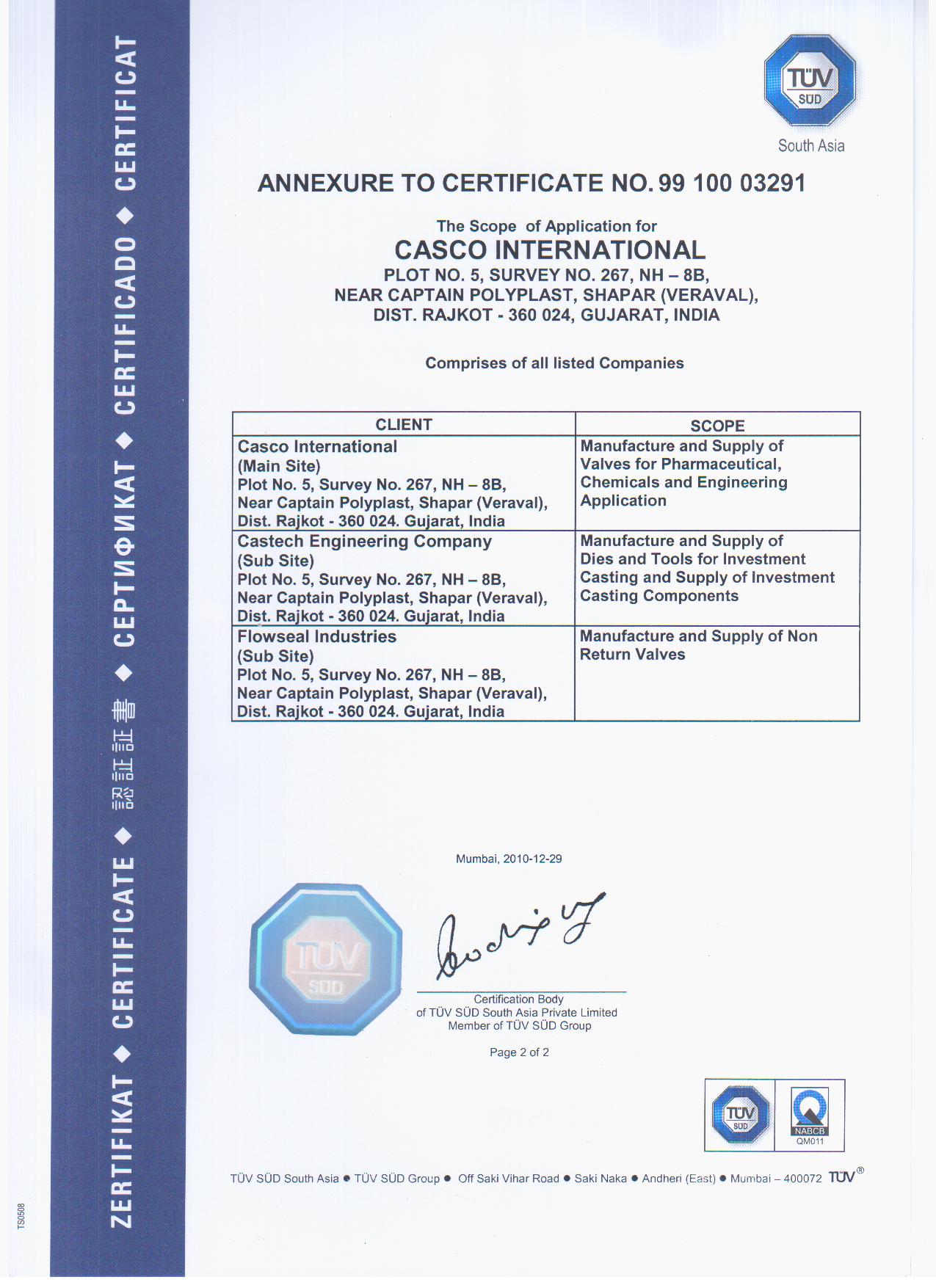

Quality Certificates

Research & Development

Continuous improvement & cost reduction to be passed to our valued customer, while increasing the value of business relationship and for this, we are concentrating on the technology & product development.

Quality Control Facilities

| Hydro/Air Testing | : In house well Equipped Air and hydro testing (Both) Facility for leakage of valves. |

| Torque measure | : In house well Equipped Digital Scale Torque measure Machine for Lever operated valves. |

| Chemical Analysis | : In- house, Spectro Meter at Foundry Division for Analysis of metal composition. |

Quality Assurance System

| Stage | Inspection | Remarks | |

| Incoming Investment Castings (Body, Connector, Ball) |

1) Dimension Inspection 2) Visual Defect Inspection 3) Chemistry Testing by spectro |

Chemical Testing by Spectro meter for each heat of casting. Produced by approved Supplier | |

| Other internal Parts | Dimension, Chemistry & Thread testing | We accept material with T. C. only | |

| In process | Machined Dimension and Thread inspection | Dimension inspection by Vernier caliber and Thread By Go & No Go gauge | |

| Assembly | Total Face to Face length Thread by Go & No Go gauge | Each Valves | |

| Final Testing | leakage Testing by Air & Torque measure by Digital Torque measuring Machine | Each & Every Valves | |

| Packing | Packing & Max. Wt. per parcel | Wooden case or Parcel Box Packing only |